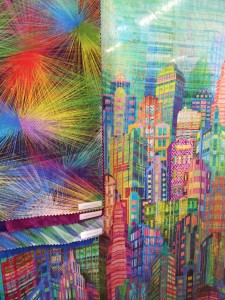

Last week I shared pictures of the Hoffman Fabrics facility in Mission Viejo, Southern California. In this blog, I’m writing about the fabrics produced by Hoffman. We began our tour with an interesting presentation from Michelle Flores, Marketing and Media Coordinator, who introduced us to the fabric manufacturing process and showed us some examples of the recently designed fabrics that were launched at Spring Quilt Market a few weeks ago. They are very excited to have recently acquired the capability of printing digitally which enables the printing of hundreds of colors in one piece of fabric and the use of much finer lines in the design. The color chip fabric has 374 different colors!

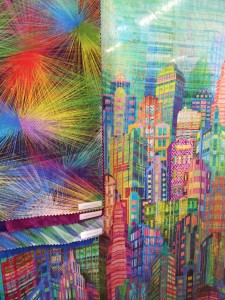

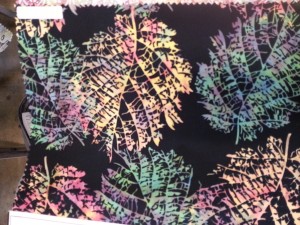

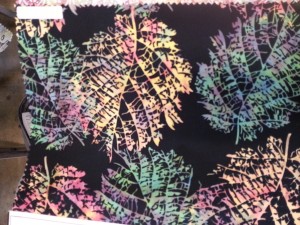

In traditional screen printing, there are usually no more than 12 colors in a fabric. Here are examples of digitally printed fabrics which illustrate the enormous array of colors. The Christmas tree quilt is made using the poinsettia fabric. These fabrics are digitally printed in Pakistan.

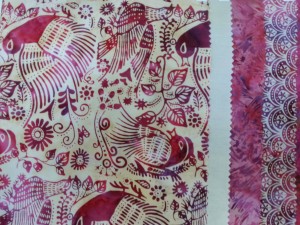

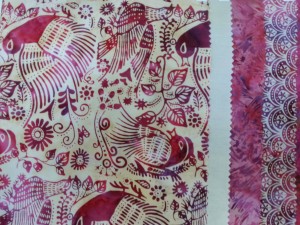

Hoffman cotton comes from a variety of sources, including the United States. All the cotton is woven overseas mostly in Pakistan, Indonesia and Java. The Hoffman prints with metallics are manufactured in Japan and 3,000 yards are printed on each run. These have as many as 10 colors which are all screen-printed by a machine, printing each color in turn onto the cloth. The metallic gold, silver or copper is applied as a paste after the rest of the printing is completed. Non-metallic prints are produced in Korea, Indonesia and Pakistan. The batiks are made in Bali and here are two recent designs.

The cotton for batiks has to be of high quality to withstand the harsh process of dyeing and hand stamping with a metal chop. Each piece of fabric is 18-20 yards long and its production goes through several steps of dyeing and over-dyeing as well as hand stamping with the chop and the application of wax to achieve the patterns. After this process the fabric is carefully checked for holes.The pictures show both sides of the chop, (one side with a handle), which is used for creating the patterns.

The chops measure 6-1/2″ x 6-1/2″ and are created from strips of copper in a steel frame fashioned in patterns copied from black and white drawings.They are dipped in wax which is stamped onto the fabric by hand. Then the fabric is immersed in a vat of dye, and later the wax is removed by boiling the fabric so that the melted wax comes up to the top of the vat and may be skimmed off. Each piece of fabric is unique.

The packs of Bali-pops are popular. Each pack contains 40 strips. There is a large cutting machine that can cut through all 40 layers at once, but each piece of fabric must be ironed by hand on a huge table and the layers neatly stacked before being sliced into strips. This attractive basket was made from one of Bali-pop packs.

All in all, a fascinating tour which I highly recommend if you have the opportunity.